-

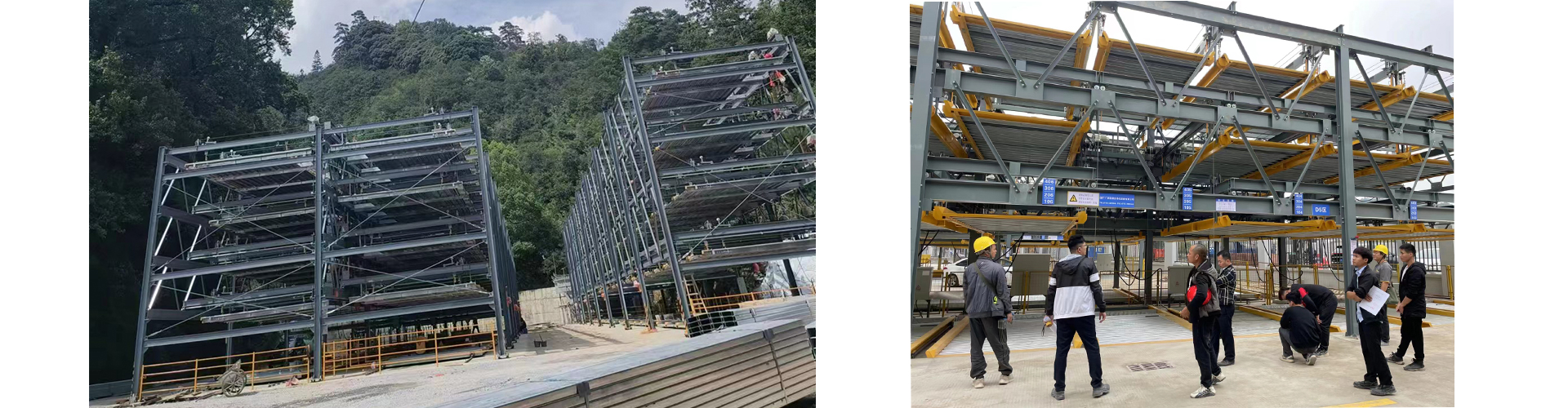

Outdoor three-dimensional parking plant

-

Outdoor three-dimensional parking plant

-

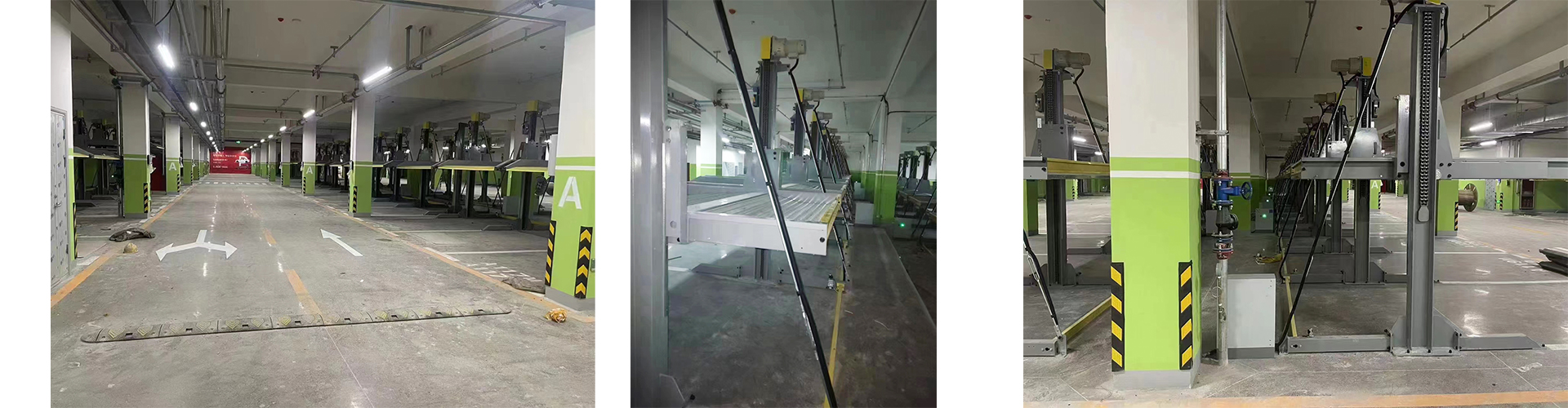

Indoor parking garage

-

Germany Parking Garage Project

-

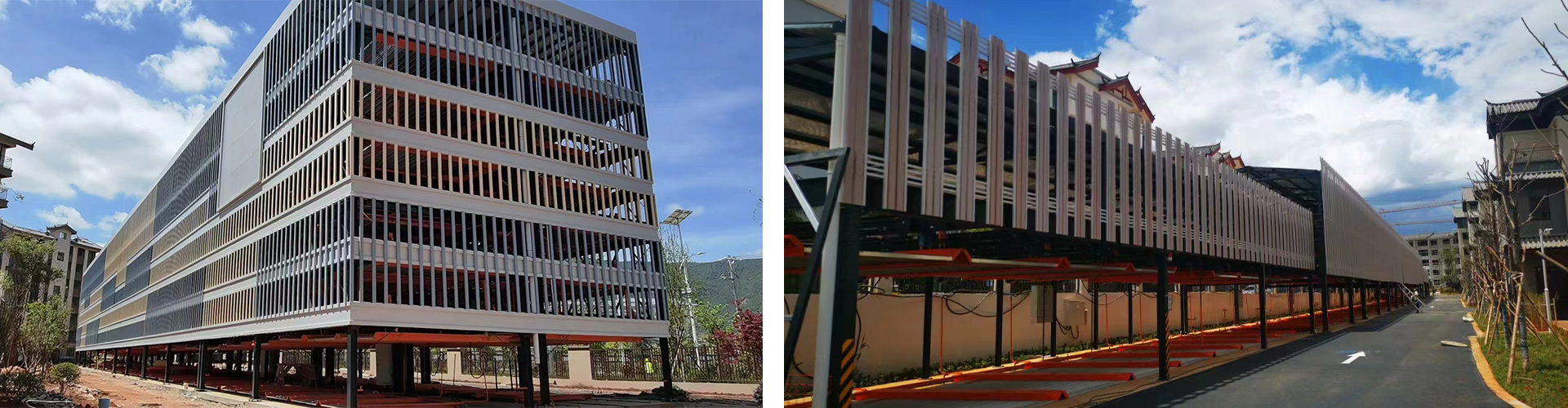

Outdoor three-dimensional parking plant

-

Outdoor three-dimensional parking plant

-

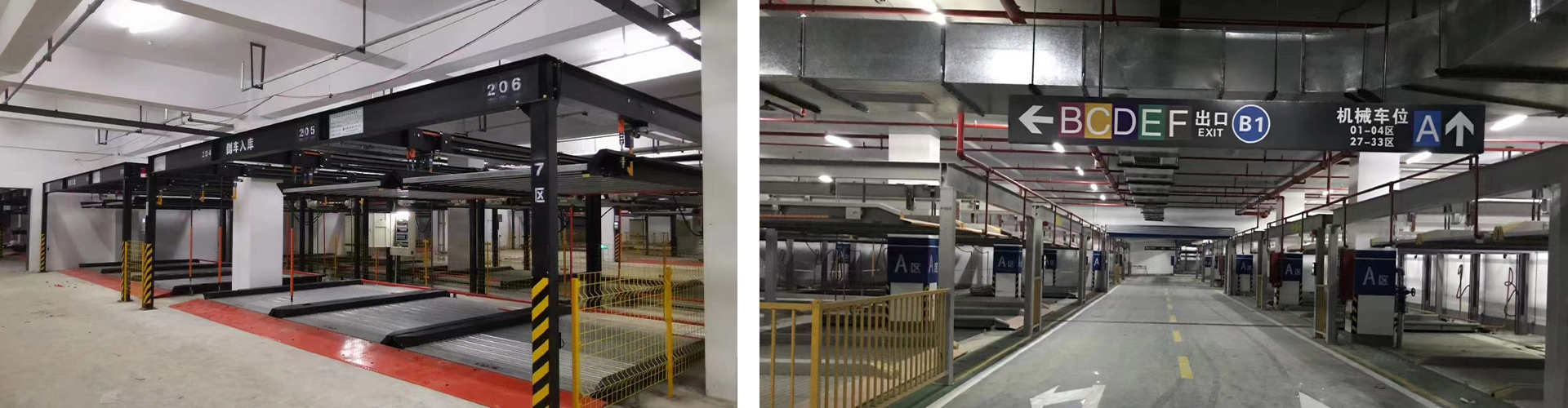

Indoor parking garage

Strength enterprise

Think globally, act locally.

The company is located in Changshan County, Quzhou City, Zhejiang Province, with many years of manufacturing experience.

employee

Our employees are reliable and trustworthy.

We have over 100 employees, with 16 dedicated to research and development.

Cooperative customers

Our products are distributed worldwide.

Our factory exports products to over 50 countries.

products

Our products

Our company specializes in the production of gear motors for multi-level parking systems.

Features:

1. Gearbox Components:

- Gears are made from low-carbon alloy steel with chromium, manganese, and titanium, carburized and heat-treated. Materials include 45, 40 chromium, 42 chromium molybdenum medium carbon steels, and medium carbon alloy steels, quenched and induction hardened for enhanced mechanical performance.

- Gears are processed using CNC machining centers for hard surface precision cutting/grinding, CNC precision grinding of inner and outer circles, and precision machining of inner and outer keyways.

- Gearbox casing is made from HT200 gray cast iron with precise casting/pressure die-casting of aluminum alloy. HT200 gray cast iron exhibits excellent compressive strength and hardness, good shock absorption, and stable installation. Aluminum alloy die-casting significantly reduces weight while supporting high torque and outstanding mechanical performance.

- The gearbox is internally filled with long-lasting lubricating grease that requires no replacement or refilling. It features imported oil seals, precision bearings, and output shafts made from alloy steel. All models undergo rigorous automatic durability and lifespan testing using simulated scenarios from our multi-level parking system testing platform.

2.From 0.2 kW to 30 kW, we offer various types of three-phase asynchronous motors specifically designed for multi-level parking systems, as well as general-purpose/inverter variable-speed three-phase asynchronous motors. They operate primarily under S2/15-minute short-term duty, S1 continuous duty, and S3/40% intermittent periodic duty cycles. They can be configured with IP54-IP57 protection ratings and paired with various types of gearboxes to form gear reduction brake motors.

The motor housings are constructed with aluminum alloy frames, fully sealed and self-ventilating, lightweight, sturdy, and excellent at dissipating heat. The motor silicon steel cores use low-loss silicon steel sheets and advanced stamping and aluminum casting technology, ensuring low power consumption and long life. Customers can choose between copper and aluminum enameled wires, with insulation ratings of B/F class. The motors operate quietly, run smoothly, deliver high torque, and exhibit strong overload capacity. The variable-speed brake motors can be combined with inverters for soft start and braking.

3.The brakes use a fail-safe braking method with optional manual release and adjustable clearance. Brake pads are made from imported asbestos-free wear-resistant materials and aluminum alloy bodies from joint ventures. High-density, high-strength springs inside the brakes produce significant braking torque, ensuring rapid and precise braking and positioning. All models undergo durability testing on our testing platform.

4.We employ internationally standardized noise testing equipment to ensure that our products meet noise emission standards upon delivery.

5.We adhere to standardized, universal, modular, serialized, and user-friendly